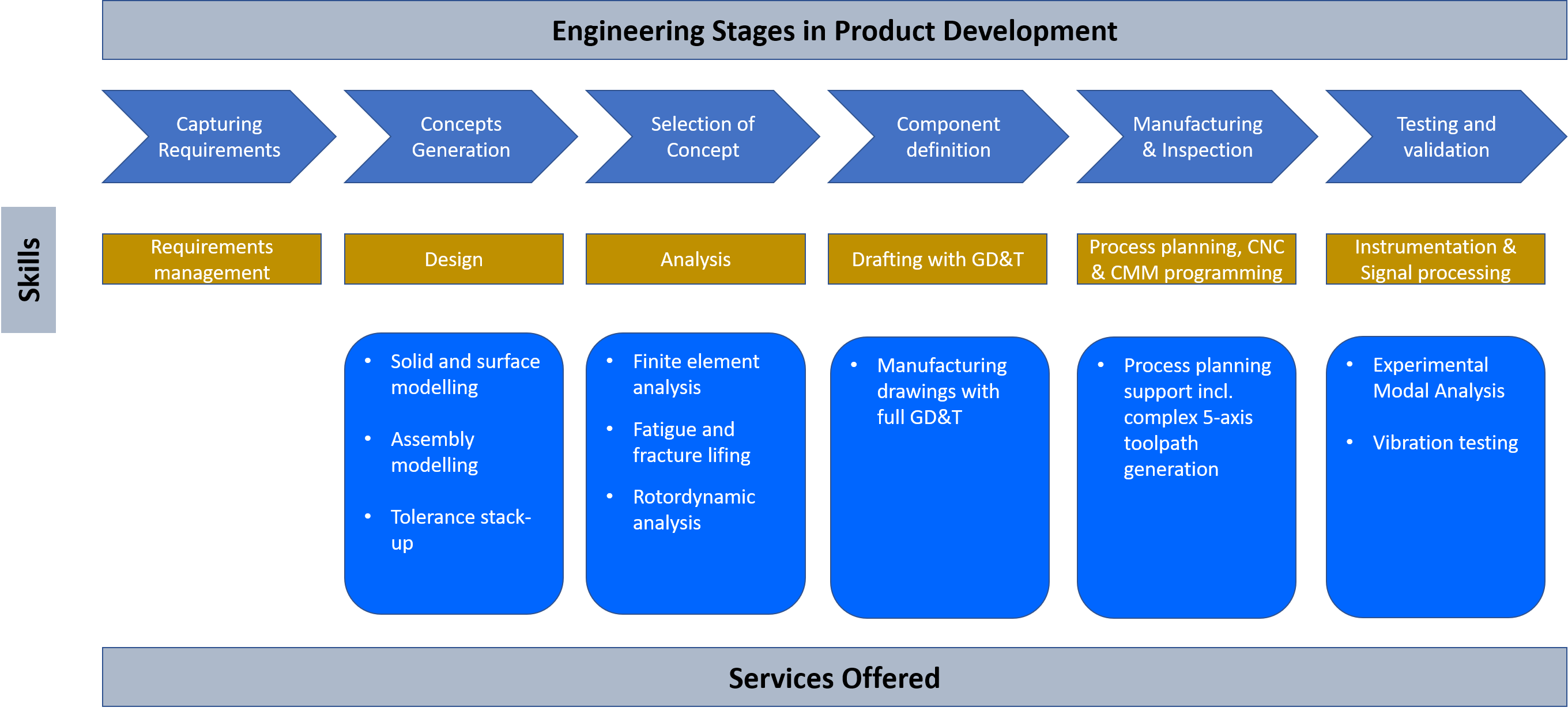

Product development

Tejas team offers services from concept generation till generation of manufacturing drawings. Engineering solutions that are cost effective and conforming to Design for Manufacturing (DfM) and Design for Assembly (DfA) best practices will be delivered. With over 40 years of experience in design, analysis and manufacturing of aerospace mechanical systems, products are designed for the highest standards of structural integrity.

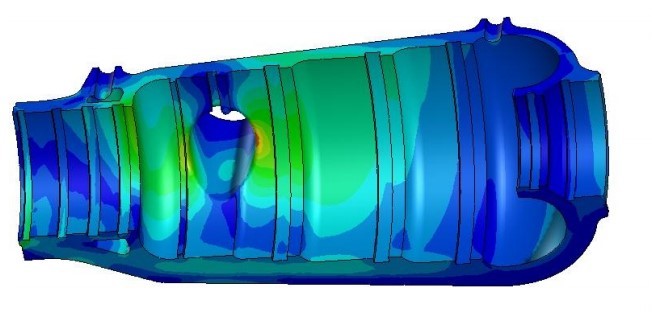

Product design and analysis is carried out according to ASME or any customer specified standard. Typical analyses carried out are:

- Linear static analysis

- Steady state and transient thermal analyses

- Non-linear: Plasticity, Viscoleasticity, Hyperelasticity

- Dynamic analyses - Modal and Harmonic analyses

- Transient dynamic analysis (implicit / explicit)

- Shock analysis as per MIL STD 810

- Random vibration analysis

- Fatigue (HCF, LCF, accumulated damage and residual life prediction)

- Stress intensity calculations and crack propagation lifing

Manufacturing drawings with full GD&T will be generated by ASME GDTP Y14.5-2009 certified professionals. Manufacturing process planning support can also be offered.

In addition to product development, Tejas team also offers services in engineering failure investigation and Residual Life Assessment (RLA) of steam turbines. We have combined experience of over 30-man years in conducting root cause investigation of steam turbines and aerospace components.